Isku-darka Budada Qoyan ee Taxanaha HLSG iyo Granulator

Astaamaha

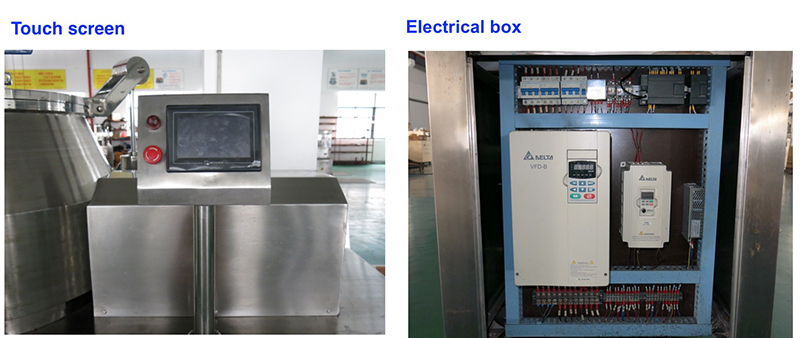

●Iyada oo la adeegsanayo tignoolajiyad barnaamijaysan oo joogto ah (is-dhexgalka mashiinka aadanaha haddii la doorto), mashiinku wuxuu heli karaa hubinta xasilloonida tayada, iyo sidoo kale hawlgal gacan-ku-qaad ah oo fudud si loogu fududeeyo halbeegga tignoolajiyada iyo horumarka socodka.

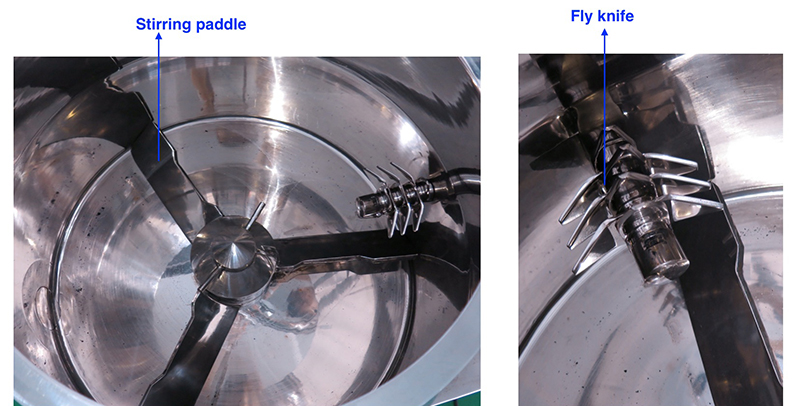

●Samee hagaajinta xawaaraha soo noqnoqda si aad u xakameyso daabka walaaqaya iyo jarista, si fudud loo xakameyn karo cabbirka walxaha.

●Iyada oo usha wareegsan ay si hawo leh u buuxsantay, waxay ka hortagi kartaa in dhammaan boodhka uu is dul saaran yahay.

●Iyada oo qaab-dhismeedkeedu yahay haan koontarool ah, dhammaan walxaha waxay noqon karaan wareeg isku mid ah. Haanta waxaa la dhigay lakab dhexdhex ah oo salka ku yaal, kaas oo nidaamka wareegga qaboojinta biyaha oo leh waxqabad heerkul sare leh marka loo eego nidaamka qaboojinta hawada la dhigo, taas oo horseedaysa in la hagaajiyo tayada walxaha.

●Iyada oo si toos ah loo qaadayo daboolka digsiga, meesha laga saaro taangiga oo la jaanqaadaysa qalabka qalajinta, oo leh jaranjaro gacan oo iskeed u qalabaysan, way fududahay in la shaqeeyo.

●Afka laga soo saaro walxaha ayaa isu beddelay qaab qaanso, iyadoo laga fogaanayo meelaha aan la arki karin.

Mabda'a Shaqada

1. Hawshu waxay ka kooban tahay laba barnaamij oo ay ku jiraan isku darka iyo granulating.

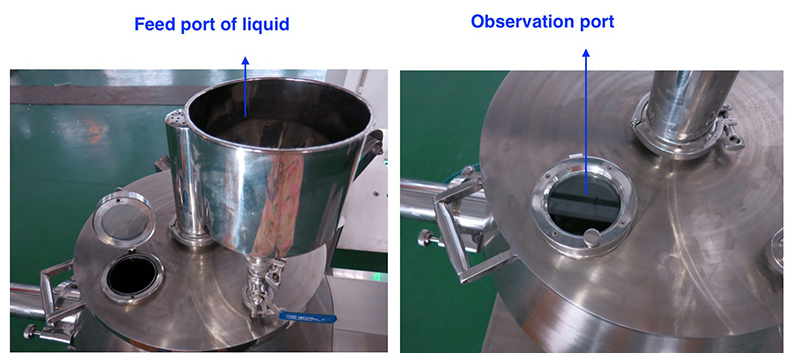

2. Budada mitirka ah waxaa lagu shubi karaa digsiga walxaha laga soo qaadayo weelka koonka ah waxaana lagu sii wadi karaa inuu ku wareego weelka iyadoo la adeegsanayo daab isku darka marka weelka la xiro. Dhanka kale, dhammaan walxaha waxay ku koraan qaabka buundada dareeraha ah iyadoo la adeegsanayo saameyn joogto ah oo ka timaadda derbiga koonka ah. Iyada oo la adeegsanayo xoqidda, is-xoqidda iyo burburka daabka iyo derbiga koonka ah, dhammaan walxaha si tartiib tartiib ah ayaa loo rogaa si loo dabciyo. Ugu dambeyntii, inta la furayo godka rajada, walxaha biyaha leh ayaa lagu riixaa saamaynta centrifugal ee daabka.

3. Walxaha jilicsan waxaa la sameeyaa iyadoon ku xirnayn saameynta qasabka ah ee lagu shubo, si sax ah; inta badan walxaha yaryar iyo kuwa isku midka ah waxaa la sameeyaa ka dib marka si joogto ah loo jaro iyadoo la raacayo xaalad isku mid ah oo dareere ah. Guud ahaan, mashiinkani wuxuu xaqiijin karaa isbeddelka labada dhinac ee u dhexeeya walxaha kala duwan.

Tilmaamaha

| Moodel | Wadarta Mugga (L) | Qadarka ugu Badan ee Dalacaadda Walxaha (kg) | Awood (kw) | Xawaaraha (r/daqiiqo) | Awoodda Helikobtarka (kw) | Xawaaraha Jeermiska (r/daqiiqo) | Cabbirka Guud (mm) | Miisaanka (kg) |

| HLSG10 | 10 | 1-3 | 2.2 | 30-500 | 0.8 | 300-3000 | 1150*1500* 550 | 260 |

| HLSG50 | 50 | 10-22 | 5.5 | 30-500 | 1.5 | 300-3000 | 1980*1500* 760 | 400 |

| HLSG100 | 100 | 15-40 | 11 | 20-300 | 4 | 300-3000 | 2200*1560* 870 | 1540 |

| HLSG200 | 200 | 30-100 | 15 | 25-500 | 4 | 300-3000 | 2500*1400* 2000 | 1100 |

| HLSG300 | 300 | 100-130 | 22 | 10-150 | 7.5 | 300-3000 | 2400*1000* 1685 | 1800 |

| HLSG400 | 400 | 130-150 | 22 | 10-150 | 7.5 | 300-3000 | 2500*2240* 1200 | 2260 |

| HLSG600 | 600 | 160-210 | 30 | 30-150 | 11 | 300-3000 | 2600*2630* 2330 | 3000 |

Qaybaha alaabta

Warsideheenna Todobaadlaha ah

Waa xaqiiqo muddo dheer la hubiyay in dib-u-habeyntu ay ku qanacsanaan doonto

akhrin kara bog marka la eegayo.

-

Iimayl

-

Telefoon

-

Whatsapp

-

Sare